Polyethylene (PE) pipe is a cost effective and proven method for running underground gas lines to indoor and outdoor gas-fired equipment, including stoves, grills, hot tubs, fire-pits and heaters. The low cost, coupled with the fact that PE pipe doesn’t rust or corrode like metal pipe, has polyethylene pipe composing over 90% of all gas pipe installations in the United States. With the use of PE pipe being so prevalent, it makes sense to have an simpler solution for connecting underground gas lines.

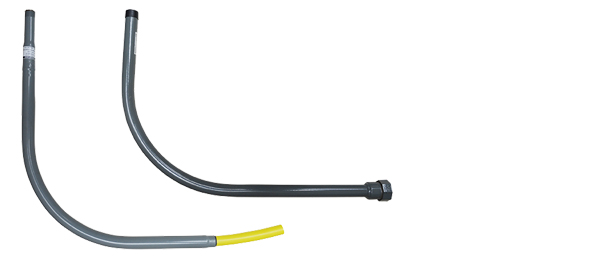

Underground Poly-Pipe Fittings

These state-of-the-art underground gas compression fittings join polyethylene pipes together in both natural gas and propane systems. They offer a quick and easy solution when compared to other joining methods, as no special tools or skills are required to operate. If a compression fitting is installed and the location requires disassembly for maintenance, the joints can be broken and assembled once again without damaging the connection. At EGW Water & Plumbing, we offer a variety of underground poly-fittings, ranging in size from ½” to 2″, including couplings, tees, elbows, and adapter fittings.

Installation and Application

With our line of underground gas compression fittings, making polyethylene pipe joining is easier than ever! Just cut your pipe, insert the included internal stiffener and tighten the nuts. There’s no need to chamfer the pipe—just smooth away any burrs. They come ready to use straight out of the package without the need to assemble anything. You can use these advanced fittings with any ½” to 2″ sized IPS yellow polyethylene gas pipe that’s approved for use with natural gas and propane.

TECHNICAL DATA

Materials:

- Nut and Main Body – Polypropylene

- Spacer – Nylon

- O-Ring – Nitrile

- Stiffener – Acetal

- Grip Ring – Acetal

They offer a max operating pressure of 125 PSIG.

Click here to download spec sheets.

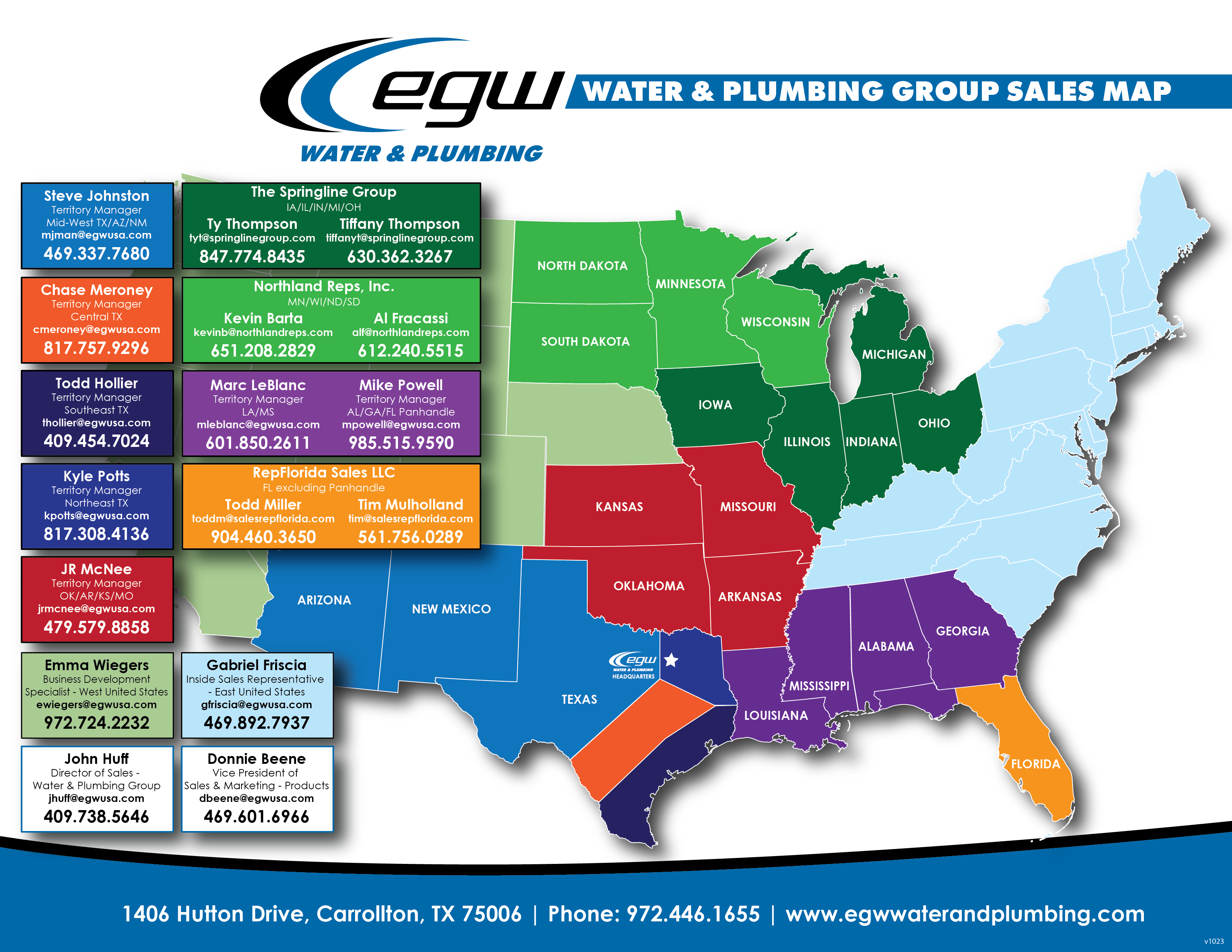

For more information on our line of underground gas compression fittings or polyethylene pipe, contact our team at EGW Water & Plumbing today! Give us a call at 972.446.1655 or use our contact form to drop us a message.